Resin Printing 101

What is Resin Printing?

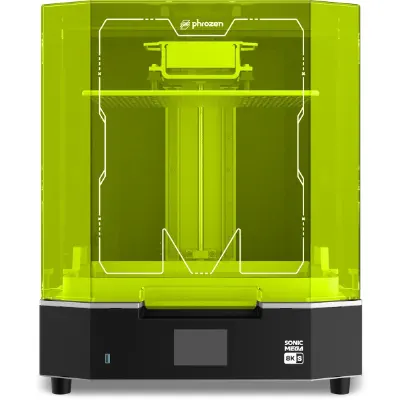

Resin printing uses the SLA, MSLA, or DLP process to create 3D objects out of a UV (ultraviolet) photopolymer.

The majority of consumer resin printers use MSLA (masked stereolithography).

What can I print with Resin?

The majority of consumers use resin printing to create miniatures, game pieces, lithographs, and other trinkets.

The engineering side of resin printing allows for commercial prototypes and complex objects made from flexible, ceramic, and high-temperature resins.

How much does Resin Printing cost?

Consumer resin printers cost $200-2,000 depending on the machine quality, build volume, and resolution. Budget resin is typically $25-40 per kilogram, while engineering resins are often $40-150 per kilogram.

An entire setup for a small resin printer typically starts around $300, while a medium printer setup will be $500 at minimum. The addition of a wash & cure or ultrasonic cleaner will be one of the most expensive add-ons.

Consumables include the screen, FEP, resin, gloves, and solvents such as IPA. The LCD screen can last up to 2,000 printing hours. The FEP can last a few hundred hours but substantially less when damaged.

| Entire Small Resin Printer Setup | $300-500 |

| Entire Medium Resin Printer Setup | $400-800 |

| Small Resin Printers | $200-500 |

| Medium Resin Printers | $300-700 |

| Large Resin Printers | $700-2,000 |

| Budget Resin | $25-40/kg |

| Engineering Resin | $40-150/kg |

| Replacement Screens | $40-150 |

| Replacement FEP or PFA | $5 |

What do I need at bare minimum?

These are some of the basic items needed for resin printing.

- Resin Printer ($200-2,000)

- STLs and Slicing Software (Free)

- Resin ($25+)

- IPA or Cleaner ($2-5 per liter)

- Nitrile Gloves ($15+)

- Respirator ($20-40)

- UV Lamp ($20)

- Turntable ($10)

- Metal Funnel ($10)

What is optional but useful?

These are some of the useful items for resin printing.

- Wash & Cure ($100-250)

- Ultrasonic Cleaner ($60-300)

- Flexible Plate ($15+)

- Extra FEP ($5+)

- Silicone Mats ($10)

- Baster ($5)

- Microfiber Cloths ($15)

- Soft Toothbrushes (<$10)

Example of a resin print session

- Turn on the heater for the printer, grow tent, and/or resin to warm everything up. Make sure the area is ventilated.

- Slice the STL and put it on the USB, then into the printer.

- Put on all appropriate PPE e.g. gloves, respirator, glasses, etc.

- If resin is in a bottle, shake and pour. If resin is in the vat, make sure it has not separated.

- Double check for cured pieces in the vat with a scraper or your finger with a glove on.

- Make sure the vat is screwed down and the acrylic cover is on, unless inside a grow tent.

- Start the print and you should hear the first few layers separating from the FEP.

- Once finished, pop the print off and remove the supports.

- Squirt some fresh IPA onto the print over a container to remove a considerable amount of uncured resin.

- Place the print in the wash & cure or ultrasonic cleaner to remove the remaining uncured resin.

- Let the print dry, then place it in the wash & cure for post-curing or on a turntable in front of a UV lamp. The print should not be sticky.

- Wet sand the print if needed. Clear coat or paint the print if desired.

- Turn off all equipment. The resin can be left in the vat if there is no debris, otherwise filter it back into the bottle.

- Throw away disposable gloves. Clean reusable gloves with IPA and UV. Clean tools and any spills. Contaminated IPA can be reused or put into the sun to cure the resin. Lid off will evaporate the IPA, whereas lid on will allow filtering reuse. IPA can be recycled using distillation.

How can I clean prints?

Resin prints have uncured resin on them after being pulled off the build plate. This resin can be removed manually or automatically.

Uncured resin can be removed manually by squirting IPA on prints, dunking the prints in containers like a pickle jar, or dabbing with a paper towel.

Cleaning automatically has a higher initial cost but reduces labor and the risk of skin exposure. Automatic cleaning of resin prints is typically performed with a wash and cure machine or an ultrasonic cleaner. In either case, the print should be cleaned until it is no longer tacky.

What to do with used IPA?

IPA (plus other cleaners like Mean Green) can be used to remove uncured resin from prints. The IPA can be reused multiple times until it becomes saturated with resin. The IPA can then be evaporated or recycled.

If cost is not an issue then evaporating contaminated IPA is the easiest thing to do. Just place the IPA outside in direct sunlight so that it will evaporate faster and the resin will cure. The cured resin can be disposed of as regular trash. Do not pour uncured resin down the drain.

IPA saturated with resin can be cured then manually filtered with a coffee filter. This eliminates resin debris but the process is imperfect. Distillation will recycle the IPA into a pure form, but it does have safety risks.

How does heat or cold affect printing?

The ideal temperature range for most budget resin is 20-30°C. Some manufacturers recommend printing only above 25°C, especially for engineering resins.

When resin is too cold it will not cure properly, so a heat source is needed. The heat source can be a heat pad, ceramic heater, space heater, or even non-UV lights like sodium bulbs.

When resin is too warm (40-50°C), the supports and resin part can lose rigidity and fail. Higher temperatures can also reduce the life of electronics such as the screen.

Resources for Resin 101

- 4D Filtration - Resin vs Filament - https://4dfiltration.com/resources/3d/resin-vs-filament-strength-quality-cost.html

- 4D Filtration - Heating Resin Printers - https://4dfiltration.com/resources/heating-resin-printers.html

- Aris Alder - Recycling IPA - https://www.youtube.com/watch?v=OJICX2-907I

- Aris Alder - Ultrasonic Cleaning with IPA - https://www.youtube.com/watch?v=J6I7HaXKV0k

- Aris Alder - Jewelry from Resin - https://www.youtube.com/watch?v=O9EmKcI_B7Q

- Doug Napier - Jewelry from Resin - https://www.youtube.com/watch?v=SRP3AlUnrSw

- Elier Olivos - Jewelry from Resin - https://www.youtube.com/watch?v=bnlQgUD_-uw

- ItsLitho - Creating Lithophanes - https://itslitho.com

- Formlabs - 3D Dimensioning - https://formlabs.com/blog/understanding-accuracy-precision-tolerance-in-3d-printing/

- Formlabs - Painting Resin Prints - https://formlabs.com/blog/how-to-prime-and-paint-3d-prints/

- Squidmar Miniatures - Painting Miniatures - https://www.youtube.com/watch?v=S7-At4qVC84